Crider Foods case study

Contact us for a quote

The business

Since the 1970s, Crider Foods has been a producer, supplier and marketer of shelf-stable and fully-cooked products among customers in retail, food service and education sectors. Crider holds Safe Quality Foods (SQF) Level 3 status — a third party certification that emphasizes Crider’s dedication to safe and wholesome food.

The problem

Crider had concerns over whether existing hand dryers were hygienic and safe for their food manufacturing environment. Additionally, because there were separate areas to wash and dry hands, water dripped onto the floor and increased risk of injuries. When Crider began new construction and rehab projects at its facility, it made the decision to find technology that offered a more hygienic, safe and fast experience.

The solution

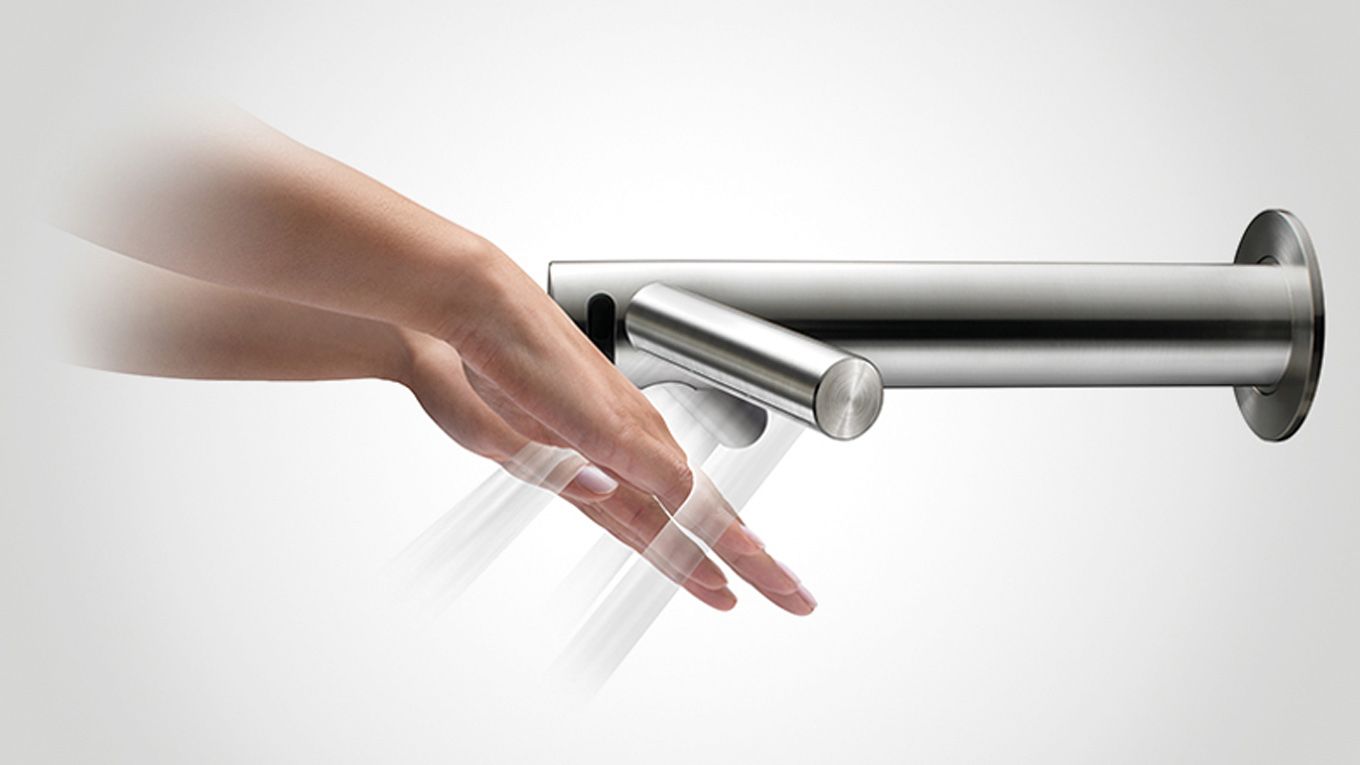

Norman Scalf, Projects Engineer, contacted Dyson for an Airblade™ technology demonstration upon the request of Mr. Crider. The Dyson Airblade Tap hand dryer reduced water on the floor and saved space. The management team were impressed and elected to install Dyson Airblade Tap hand dryers in Crider’s washrooms and wash-in areas.

Features

-

Faster dry times

Other hand dryers can take up to 43 seconds to dry hands. The Dyson Airblade Tap hand dryer uses two high-velocity sheets of air to scrape water from hands – drying hands in less than 14 seconds.¹

-

No water on the floor

With Airblade™ technology in a tap installed with a SYSPAL unit, hands are washed and dried at the sink. Washroom users don't have to move to a separate area to dry hands, so no water is dripped on the floor.

-

More space in the washroom

A Dyson Airblade Tap hand dryer removes the need for a separate drying area – unlocking valuable wall and floor space in the washroom that can be used for other important facilities, such as extra cubicles.

Contact us for a quote

/b2b-overview/B2B-Explore-Dyson_Range.jpg?$responsive$)

Explore the Dyson for business range

- 1 Dry time determined using Dyson test method 769 based on NSF P335 using a measurement of 0.1g residual moisture.